In addition, our Energy Management Team has been in place since 2008. This team seeks to ensure that our facilities have reliable, cost effective energy supplies, with a focus on conservation, to reduce our overall energy usage. Acushnet maintains a long standing interest in energy conservation, and regularly explores and implements renewable energy opportunities such as solar and wind. Corporate policy requires that that all capital projects funding requests to be accompanied by a 'Project Impact Report' that requires project managers to identify the impact (positive or negative) on energy consumption and the environment. This impact is one of the key criteria we use to determine how to allocate capital funds. We also dedicate resources to studying and understanding all the latest incentives provided by Federal, State and local utility programs to ensure that capital dollars are invested in the most cost effective manner possible.

Examples of past and current initiatives include:

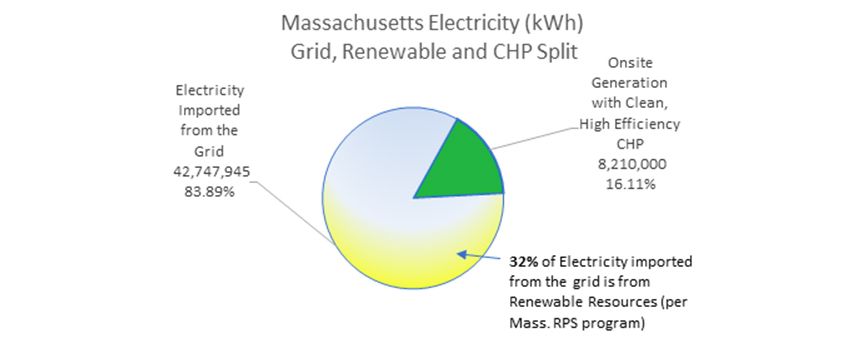

- In 2020, our U.S. golf ball manufacturing facilities received 32% of their electricity needs directly from renewable sources. Between 2012 and 2014, we provided leadership in the early stages of large scale solar development in Massachusetts by entering into long-term "virtual net metering credit agreements" for five large scale solar farm projects. By committing to purchase 100% of the utility bill credits associated with over 17,000 MWhs generated annually by these facilities, Acushnet played a critical role in financing the projects and bringing them online.

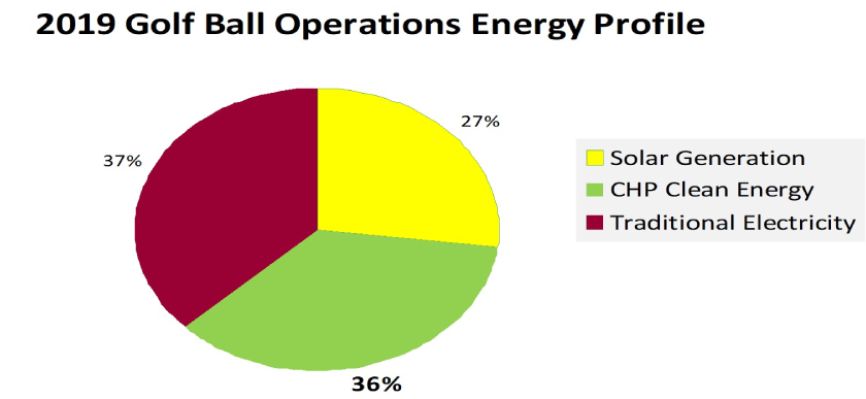

- Our U.S. golf ball manufacturing facilities meet nearly 30% of the plants' energy needs from solar farm projects, equaling the energy needed to power over 2,100 homes annually.

- In 2020, we renewed our commitment to invest in highly efficient Combined Heat and Power ("CHP"), a technology proven to operate at higher efficiency and lower emission rates compared to the equivalent import of electricity and burning of fossil fuels, for process operations and to heat the facilities. The 2020 project at Ball Plant II marks our third major capital investment in CHP and replaces an aging CHP system with a more reliable, state-of-the-art CHP system that will provide many years of highly efficient, on-site, heat and power production with cleaner emissions.

- Cogenerating units at our U.S. golf ball manufacturing facilities supply clean energy from natural gas that meet over 35% of the plants' energy needs, equaling the energy needed to power over 2,900 homes annually. These high efficiency cogeneration systems take exhaust heat generated from these units and cycle it back into our processes and also use this energy to heat the facilities. In 2015, we were recognized as a "Clean Heat and Power Champion" by the Northeast Clean Heat and Power Initiative and, in 2009, we were the inaugural recipient of the Massachusetts Department of Energy Resources 'Beacon of Energy' award for our achievements in energy utilization from alternative energy sources.

- We have installed a battery energy storage system at our Ball Plant 2 to store excess energy for use during peak demand periods, easing stress on the power grid.

- Our Thai golf ball facility received the 'Green Star Award' from the Thai government, signifying excellence in environmental management, environmental best practices and community engagement.

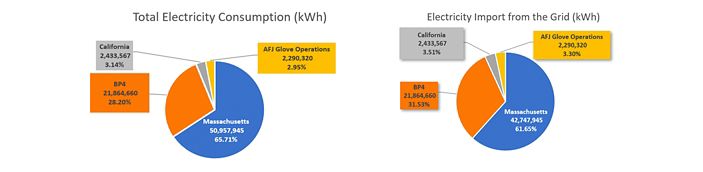

- Energy to run the golf ball and club manufacturing operations is primarily electricity. In 2020, golf ball manufacturing facilities worldwide and the primary golf club manufacturing facilities in the US. combined used just over 55,400 megawatt hours.

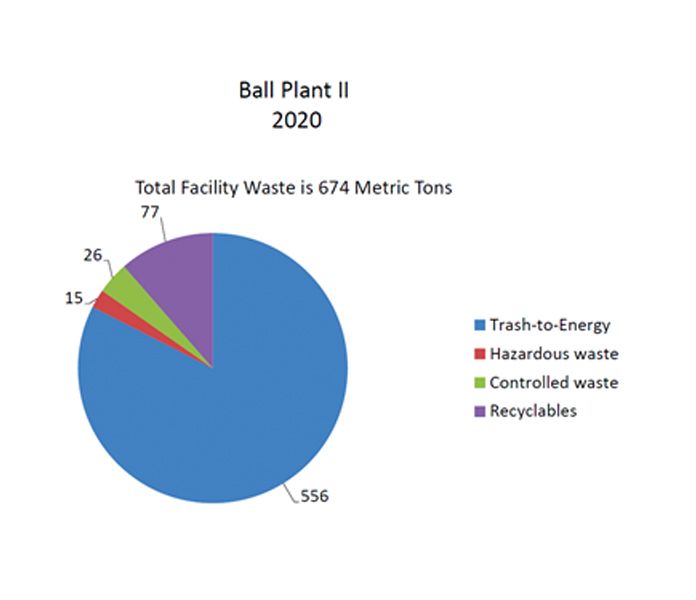

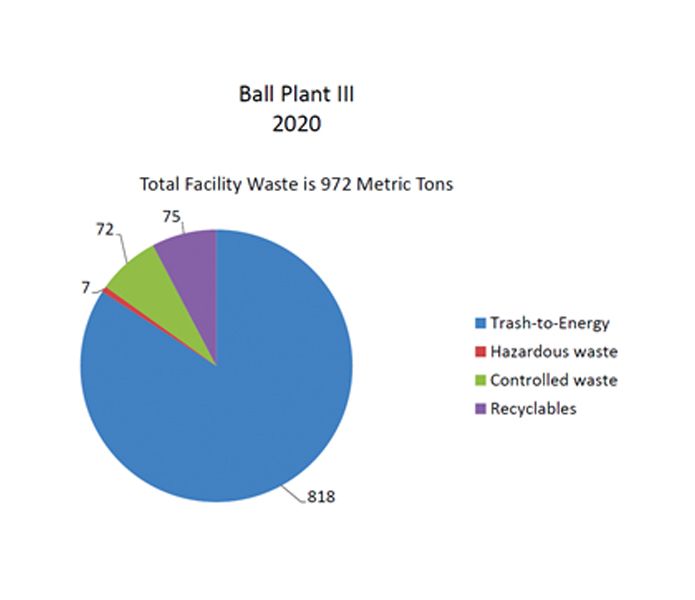

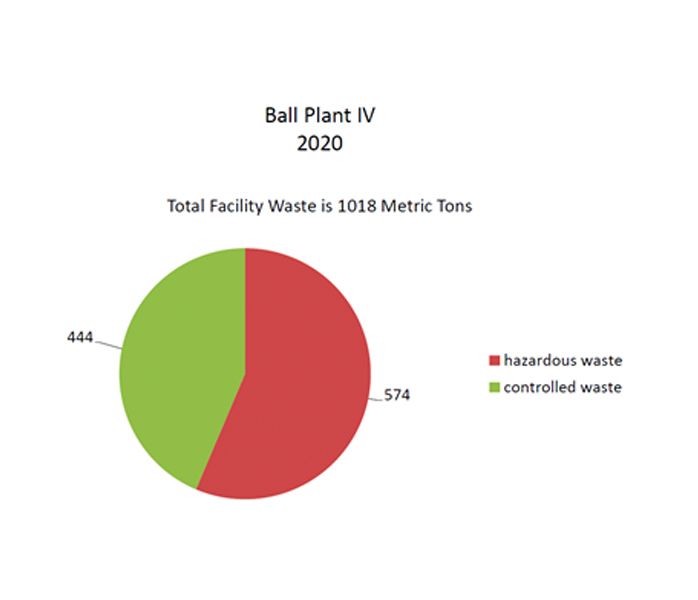

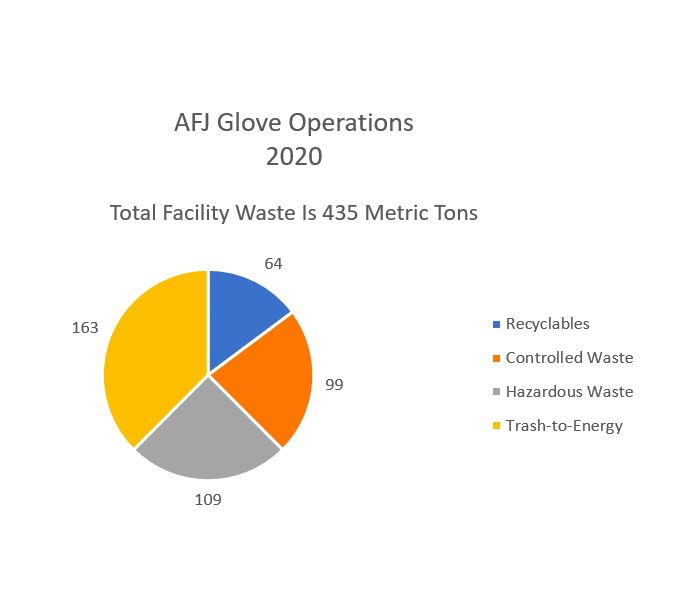

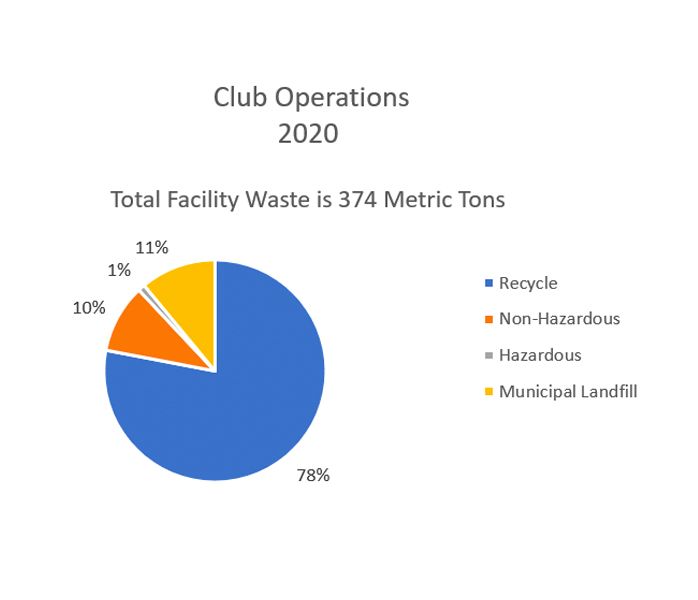

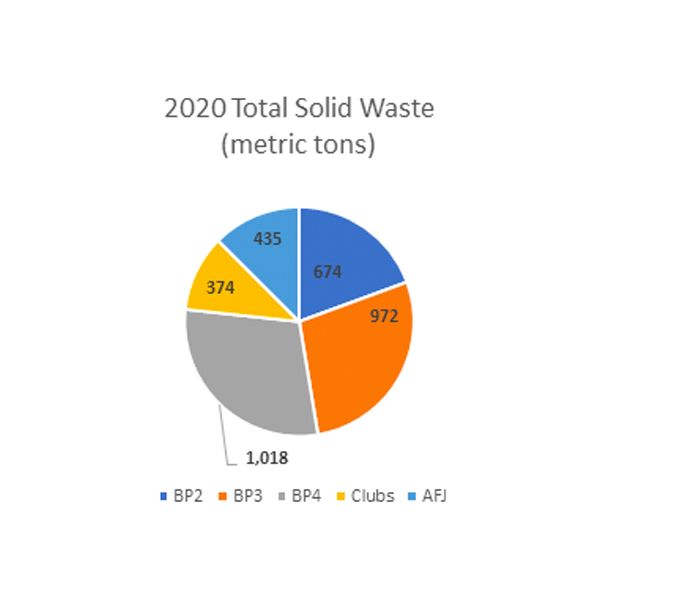

- Acushnet Company continuously strives to minimize its environmental impact from manufacturing operations. Hazardous waste generation has been minimized through formal team evaluation and review. Cross-platform team members rely on experience to guide manufacturing advances to maximize raw material use, inherently minimizing all wastes. Efforts also focus on less toxic raw materials. We have a long history of source reduction and recycling programs aimed at landfill diversion and the use of non-VOC solvents and particulate control devices to mitigate any environmental impact to the community. In 2020, U.S. golf ball and golf club operations achieved a 93 and 87 percent recycling rate, respectively, diverting more than 1 million kilograms and over 1/4 million kilograms, respectively, of material from the landfill, and less than 1.5 and 1 percent, respectively, of all solid waste is regulated as a hazardous waste.

- We have comprehensive recycling, waste reduction, water conservation and reduction programs in our manufacturing facilities worldwide. In 2019, our factories made significant efforts to recycle process waste and the majority of the waste generated at our Golf Ball Operations was converted into energy:

- We monitor various regulatory lists of toxic/hazardous substances through regulatory tracking databases and regulatory alert services for any substances that may be of potential concern for our products. We then review all new ingredients through our approval system to ensure that these materials are not included in products or are present only in amounts below any regulatory thresholds. Monitoring is supplemented with written certifications from suppliers concerning the presence of harmful chemicals in their products, such as TCLP constituents, REACH Restricted Substances or Substances of Very High Concern, and chemicals that are subject to the Toxic Substances Control Act. Natural Gas is the only other energy source, and over 917 million cubic meters were consumed in 2020.